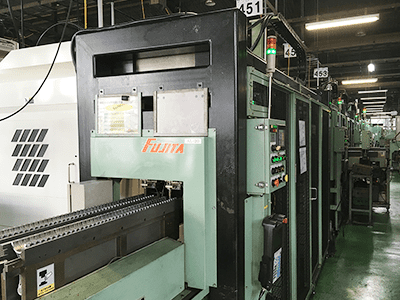

Machining is to cut a part from the work object.

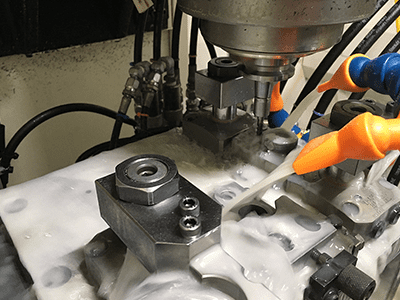

We do machining with lathe turning, drill boring, milling, broaching. When we use lathe turning, we make the work object turns and put it to a cutting tool. This method is mainly used for crankshaft process.

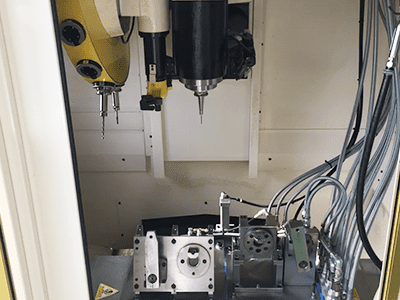

Boring process is to make a hole in the object work by a drill. This process is the most frequent process of all in our factory.

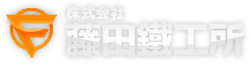

Milling process is to cut a locked object work by a rotating cutting tool. This process is used for faces of assembly connecting rod and crankshaft shaping.

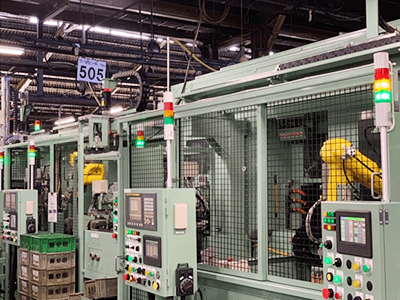

Broaching process is to cut a locked object work by pulling an elongated cutting tool. This process is used for shaping a spline and both sides of assembly connecting rod shaping.